What is waterproofing in Circus Hartfield articles? It plays a crucial role in protecting structures from water damage and ensuring their long existence. Whether it’s preserving historic buildings, safeguarding modern homes, or fortifying underground tunnels, waterproofing serves as the first line of defense against water intrusion. This process has evolved from simple natural materials like clay and tar to cutting-edge technologies designed to withstand the harshest conditions. In this article, we’ll dive into the fascinating history, the methods used today, and the practical applications of waterproofing. Along the way, we’ll address its impact on construction, its challenges, and why it remains indispensable in old and new projects.

Table of Contents

The Fascinating Evolution of Waterproofing

Waterproofing has a rich and varied history that reflects humanity’s ability to adapt to water-related challenges. As societies grew and construction advanced, the need for effective waterproofing became increasingly evident. What began as simple attempts to shield structures from moisture has evolved into a sophisticated science. This section explores the key milestones in the history of waterproofing, from ancient practices to modern sustainable techniques.

Early Innovations: The First Steps in Waterproofing

In ancient times, waterproofing was born out of necessity. Civilizations needed to protect their buildings, storage facilities, and transportation from water damage. Early methods were rudimentary but effective for the time:

- Clay Applications: Clay was used to seal storage containers and waterproof roofs. Its natural properties made it a practical choice for stopping water seepage.

- Bitumen and Tar: Ancient Mesopotamians used bitumen, a sticky, tar-like substance, to coat boats and waterproof structures. This method ensured durability against flooding.

- Palm Fronds and Mud: In Egypt, early builders mixed mud with natural fibres to create waterproof coatings for housing.

These practices laid the groundwork for the waterproofing techniques we rely on today, showcasing the innovative spirit of ancient civilizations.

Breakthroughs in the Middle Ages: Paving the Way

The Middle Ages saw significant advancements in waterproofing materials and applications. As building techniques improved, so did the methods for protecting structures against moisture.

- Wax and Resin Coatings: European Builders used wax and tree resins to waterproof wooden structures and ships. These materials formed a durable, water-resistant layer.

- Stone and Mortar Enhancements: Medieval masons added water-resistant additives to their mortars, creating stronger, more weatherproof stone structures.

- Canal and Bridge Construction: Waterproofing became crucial for large-scale infrastructure like canals and bridges, with engineers experimenting with natural waterproofing agents.

These breakthroughs in material science allowed for greater architectural achievements and set the stage for the next era of innovation.

The Industrial Revolution: Waterproofing Takes a Leap

The Industrial Revolution was a turning point for waterproofing. This era saw the development of synthetic materials that transformed the way water resistance was achieved.

- Rubberized Coatings: The invention of vulcanized rubber provided a flexible, waterproof material ideal for roofing and footwear.

- Asphalt and Tar Paper: Widely adopted for roofs and roadways, these materials became staples in industrial construction, offering durability and cost-efficiency.

- Waterproof Paints: Advances in chemistry led to the creation of water-resistant paints and coatings, protecting walls and surfaces from moisture damage.

These innovations enabled larger-scale construction projects, from skyscrapers to complex drainage systems, redefining what was possible in the built environment.

Modern Innovations: Sustainable Waterproofing in Focus

Today, the focus is on sustainability, efficiency, and minimal environmental impact. Modern waterproofing combines advanced technology with eco-friendly practices.

- Liquid Waterproofing Membranes: These flexible coatings create seamless, durable barriers that adapt to a variety of surfaces.

- Green Roof Systems: Designed to absorb water and reduce runoff, green roofs integrate vegetation with waterproof membranes for environmental benefits.

- Nanotechnology: Innovations in nanotechnology allow for ultra-thin waterproof, effective, and environmentally conscious coatings.

- Recycled Materials: Eco-friendly options like recycled rubber and sustainable sealants are gaining popularity in construction projects.

Why Waterproofing Matters in Foundations and Beyond

Waterproofing is a crucial element in construction, especially when it comes to safeguarding foundations. Foundations are the backbone of any structure, supporting weight and ensuring stability. However, their placement below ground level makes them highly susceptible to water ingress. This section delves into the risks of water intrusion, the role of waterproof concrete, and practical insights into its use, benefits, and maintenance.

Understanding the Risks of Water Ingress

Water ingress occurs when water penetrates structural materials, leading to a range of problems:

- Cracks and Erosion: Over time, water can cause cracks in concrete, which allows more water to seep in, accelerating erosion and weakening the material.

- Foundation Shifting: Excess moisture in the soil surrounding foundations can lead to expansion and contraction, causing structural shifts or instability.

- Mold and Mildew Growth: Persistent dampness fosters mould and mildew, creating unhealthy conditions and compromising the structure’s integrity.

- Costly Repairs: Damage caused by water ingress often requires extensive and expensive repair work, making prevention essential.

By addressing these risks, waterproofing protects both the structural integrity and the long-term value of buildings.

How Waterproof Concrete Is Made

Waterproof concrete is engineered to prevent water penetration by incorporating specific additives during its production. These components enhance the material’s resistance to moisture and improve its performance:

- Crystalline Admixtures: These compounds react with water and cement particles to form crystals that block pores in the concrete, reducing permeability.

- Water-Reducing Agents: These additives enhance the workability of concrete while minimizing the amount of water required, resulting in denser, less porous material.

- Hydrophobic Additives: Materials like silicates and silicones create a water-repellent layer within the concrete, further improving resistance.

The manufacturing process ensures a durable, water-resistant product that meets the demands of challenging environments.

The Right Time and Place to Use Waterproof Concrete

Waterproof concrete is not always necessary for every project but is essential in specific situations where water exposure is a significant concern:

- Basements and Underground Structures: These areas are constantly exposed to groundwater, making waterproof concrete a practical choice.

- Tunnels and Subway Systems: These structures require robust water resistance to ensure safety and longevity in wet conditions.

- Swimming Pools and Water Tanks: Waterproof concrete ensures these installations remain leak-free, preventing water loss and external contamination.

- Bridges and Dams: Heavy exposure to water makes waterproofing a critical component in the construction of such infrastructure.

Using waterproof concrete in these scenarios significantly reduces the risk of water damage over time.

The Pros and Cons of Waterproof Concrete

Advantages:

- Durability: Waterproof concrete lasts longer by resisting damage from water infiltration and freeze-thaw cycles.

- Low Maintenance: Once properly installed, it requires minimal upkeep, reducing long-term costs.

- Effective in Harsh Conditions: Its ability to withstand extreme environments makes it ideal for challenging projects.

Disadvantages:

- Higher Costs: The additives and specialized production processes increase initial costs.

- Installation Challenges: Improper mixing or application can lead to weak spots, compromising its effectiveness.

Understanding these pros and cons helps builders and project planners determine whether waterproof concrete is the right solution.

Common Issues and Repairs for Waterproof Concrete

Even waterproof concrete is not immune to wear and damage. Common problems include:

- Cracks: These often develop due to settling, pressure changes, or improper curing.

- Joint Failures: Expansion joints can become weak points where water infiltration occurs.

- Surface Damage: Over time, exposure to chemicals or heavy use may degrade the concrete’s protective layer.

Repair Techniques:

- Sealants and Coatings: Applying waterproof sealants to affected areas can restore water resistance.

- Injection Grouting: For deeper cracks, specialized grout is injected to fill gaps and restore structural integrity.

- Surface Patching: Damaged areas can be patched with compatible materials to renew their water resistance.

Regular inspections and timely repairs ensure the continued effectiveness of waterproof concrete.

Waterproofing in foundations and beyond is critical for maintaining the stability and longevity of structures. By understanding the risks and solutions, builders can make informed decisions to protect their projects from water damage.

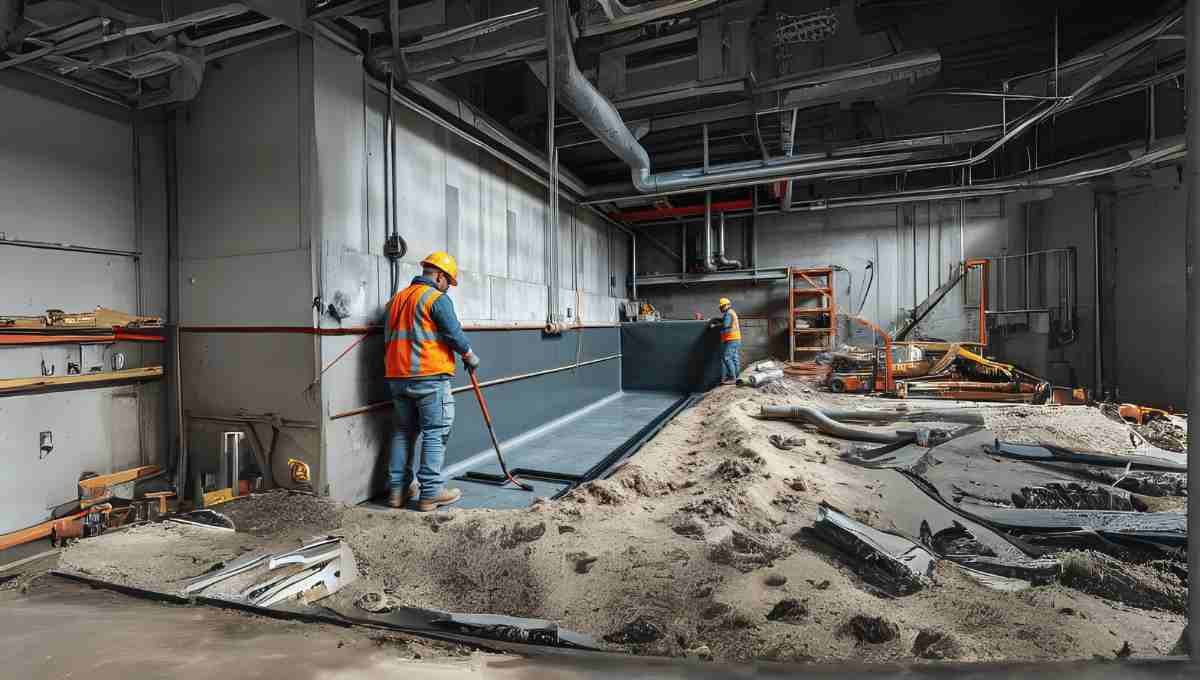

Essential Techniques for Effective Waterproofing

Effective waterproofing is more than just applying materials to a surface. It requires precise techniques, careful preparation, and regular maintenance to ensure long-lasting results. As waterproofing continues to evolve, modern approaches focus on using innovative materials and addressing potential vulnerabilities in structures. This section explores key techniques that protect structures from water damage while enhancing durability.

Preparing and Maintaining Waterproof Membranes

Waterproof membranes act as a shield, preventing water from penetrating surfaces. Proper preparation and maintenance are essential for their effectiveness.

Steps for Preparation:

- Surface Cleaning: Ensure the surface is free from dirt, debris, and oils that may interfere with adhesion.

- Repair Damages: Fill cracks and smooth uneven areas to create a solid base for the membrane.

- Priming: Apply a primer compatible with the membrane to enhance adhesion and longevity.

- Application: Install the membrane according to manufacturer guidelines, ensuring it fully adheres to the surface without gaps or air pockets.

Maintenance Tips:

- Regular Inspections: Check for signs of wear, bubbling, or detachment to address issues early.

- Reapplication: Some membranes may require recoating or re-sealing over time to maintain their effectiveness.

- Environmental Factors: Protect membranes from extreme UV exposure or physical damage, which can degrade their performance.

Properly prepared and maintained membranes provide reliable protection and extend the lifespan of structures.

Combatting Osmotic Blistering: Causes and Remedies

Osmotic blistering is a common issue in waterproofing. It occurs when moisture trapped under a waterproof layer creates pressure, causing bubbles or blisters.

Causes of Osmotic Blistering:

- Trapped Moisture: Inadequate surface drying before applying membranes can leave residual water that later expands.

- Contaminants: Salt or chemical residues on the surface can draw in moisture, exacerbating blistering.

- Poor Ventilation: Enclosed areas without airflow increase the likelihood of moisture entrapment.

Remedies for Blistering:

- Surface Preparation: Thoroughly dry and clean the surface before application to minimize trapped moisture.

- Ventilation Systems: Ensure proper airflow during application and curing to allow any residual moisture to escape.

- Repairing Blisters: Remove affected areas, clean thoroughly, and reapply the membrane to restore waterproofing.

Addressing these issues proactively can prevent blistering and ensure the effectiveness of the waterproofing system.

Beyond Concrete: Alternative Waterproofing Solutions

While concrete is a common focus, many structures require waterproofing solutions tailored to other materials like wood, metal, or composites. Alternative methods expand the versatility of waterproofing for diverse applications.

Liquid-Applied Membranes:

- Flexibility: These membranes are applied as a liquid and cured into a seamless, waterproof layer.

- Applications: Ideal for irregular surfaces, roofs, and basements.

- Advantages: Provide excellent coverage and adaptability to different shapes.

Sheet Membranes:

- Pre-Fabricated Layers: These come as rolls that are adhered or welded to surfaces.

- Applications: Often used for foundation walls, tunnels, and large flat areas.

- Advantages: Highly durable and resistant to mechanical damage.

Specialized Coatings:

- For Wood: Sealants and waterproof paints protect decks, fences, and outdoor furniture from moisture.

- For Metal: Corrosion-resistant coatings prevent rust and extend the lifespan of metal structures.

- Advantages: Tailored solutions for specific materials ensure compatibility and effectiveness.

Alternative methods offer flexibility and targeted solutions, ensuring every structure benefits from reliable waterproofing.

By using these essential techniques, modern waterproofing systems deliver superior protection and long-term performance. Proper application and maintenance ensure structures remain resilient against water damage for years to come.

Conclusion

Waterproofing is a vital element in ensuring the longevity and strength of structures. From ancient techniques like clay and tar to modern, eco-friendly solutions, waterproofing has evolved to meet the challenges posed by water ingress and material degradation.

This article has highlighted key advancements in waterproofing, including the importance of using specialized materials such as waterproof concrete and membranes, and understanding their pros and cons. Protecting foundations, combating issues like osmotic blistering, and adopting sustainable practices are essential for effective waterproofing. By understanding what is waterproofing in Circus Hartfield articles, readers gain valuable insights into the importance of this process and how it shapes construction today. Whether working with concrete, wood, or metal, prioritizing waterproofing ensures safety, durability, and peace of mind for any project.

FAQ’s

What is waterproofing in painting?

Waterproofing in painting involves applying protective coatings or sealants to surfaces to prevent water penetration. This process ensures durability and protects painted structures from water damage. Techniques mentioned in what is waterproofing in Circus Hartfield articles highlight its significance in maintaining structural integrity.

What was the worst circus fire in history?

The worst circus fire in history was the 1944 Hartford Circus Fire, where over 160 people tragically lost their lives. What is waterproofing in Circus Hartfield articles explores preventive measures that could reduce such structural vulnerabilities.

Who was the unidentified girl in the circus fire?

The unidentified girl, known as “Little Miss 1565,” was a young victim of the 1944 Hartford Circus Fire. Her identity remained unknown for decades, sparking widespread curiosity and debate, as highlighted in discussions of what is waterproofing in Circus Hartfield articles.

What is the song on the Hartford circus fire?

The song “The Hartford Circus Fire, 1944” by Tom Paxton commemorates the tragedy. It reflects on the devastating event, connecting to themes explored in what is waterproofing in Circus Hartfield articles about safety and protection.

What was the worst fire in CT history?

The 1944 Hartford Circus Fire is considered the worst fire in Connecticut history, with significant loss of life. Lessons from this event align with topics like prevention and resilience discussed in what is waterproofing in Circus Hartfield articles.